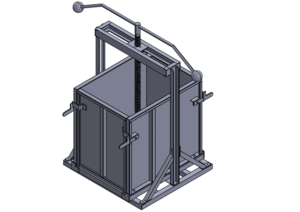

Bale Press and Bale box (3D View)

Steel Fabrication for Tobacco Agronomy

At Mamsen Engineering, we specialize in providing comprehensive agronomy services tailored to the tobacco industry. Our expertise in steel fabrication enhances our ability to support farmers and agronomists in optimizing their tobacco production.

At Mamsen Engineering, we are dedicated to supporting the tobacco agronomy sector through innovative steel fabrication solutions. By providing high-quality equipment for processing, reaping, and curing, we empower farmers to enhance their productivity and product quality.

Here are the key services we offer:

- Custom Steel Structures

- Tobacco Barns: Design and fabrication of durable and efficient tobacco curing barns. Curing Barns: We manufacture durable, weather-resistant curing barns that provide optimal conditions for tobacco drying. Our designs focus on effective ventilation and temperature control to enhance the curing process.

- The name of our Barn is Twin Turbo Barn. This barn has been accredited by Tobacco Research Board (TRB).

Main Advantages:

- Multi Fuel heat exchanger – Burns with Coal, Wood, Biomass without the use of any electrical or solar powered fans

- Our heating system can be retrofitted into existing Conventional or Rocket Brick structure barn

- Reduces coal, wood consumption by over 50 percent when compared with the Conventional barns. The curing stats are as follows: – Coal 0.86kg of Coal/kg of Cured Tobacco. Wood: – 1.75kg of Wood/kg of Cured tobacco. Combustion of coal is over 90 percent.

- Customization: We understand that every tobacco farm has unique requirements. Our team works closely with clients to design and fabricate equipment that meets their specific needs.

- Reaping Solutions

Harvesting tobacco is a labor-intensive process that requires reliable equipment. Our steel fabrication services provide transport Systems, custom steel trailers and carts facilitate the safe and efficient transport of harvested tobacco, reducing the risk of spoilage.

- Training and Workshops

Best Practices: Conducting workshops on the latest agronomy practices and technologies in tobacco farming.

Safety Training: Educating farmers on safe handling and application of agricultural chemicals.

- Research and Development

Innovative Techniques: Collaborating with research institutions to develop and implement new farming techniques.

Sustainability Practices: Promoting sustainable farming practices to reduce environmental impact.

We offer the following products & services to the tobacco sector:

Tobacco curing solutions – We are the inventors of the innovative twin turbo tobacco curing barn.

Tobacco Storage racks – We have a several designs available and cater to our clients’ requirements. We have supplied over 75,000 tobacco storage racks to clients throughout Africa

Slat and Belt Conveyor systems – We manufacture a range of conveyor systems

to cater to all tobacco handling needs.

Tobacco loading and offloading platforms – We have supplied several loading platforms and bag stackers to companies within the Tobacco sector.

Tobacco handling solutions – We have a range of tobacco handling products on offer such as Tobacco bale presses and bale boxes, Tobacco sack barrows and Tobacco Bale trolleys.

Tobacco processing plant equipment – We manufacture a range of tobacco processing plant equipment such as counter flow coolers, shaker screening tables.

Tobacco Handling equipment – We manufacture a range of Tobacco handling equipment such as sack barrows and sack trolleys.

Fabrication and maintenance work – We fabricate all structural and mechanical components as well as provide skilled labor to carry out maintenance works.