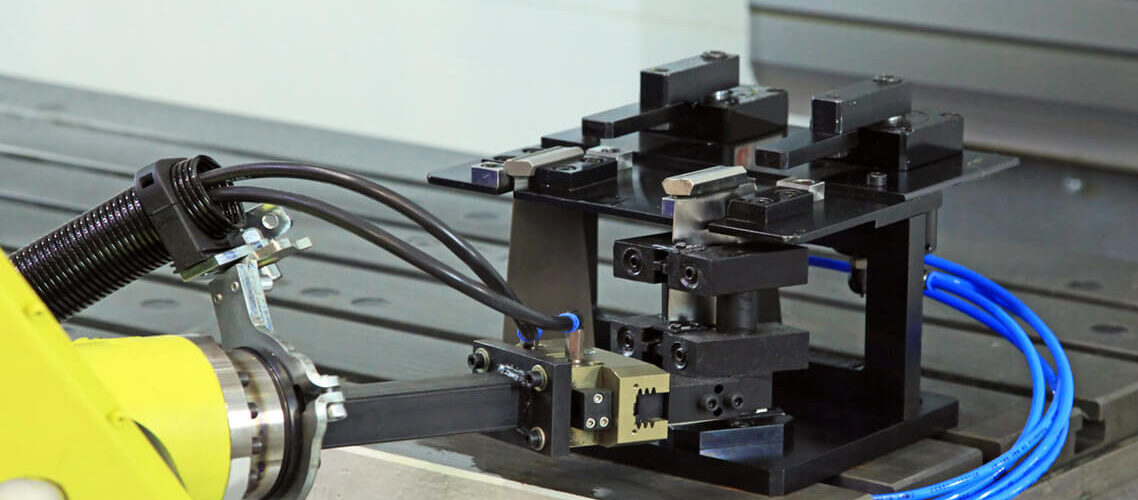

Mamsen Engineering provided comprehensive engineering services for The Zimbabwe Fertiliser Company to enhance the efficiency and capacity of their fertiliser production processes. Our team was responsible for designing and optimizing the fertiliser drier drum, including the fabrication and rolling of the rotary cylinder and tire which were both made from 16mm plate. This upgrade to their plant has resulted in increased production efficiency, reduced downtime, and greater operational reliability, ensuring the company’s ability to meet growing market demands for agricultural inputs in the region.

|

Fertilizer dryer drum

|

|

|---|---|

|

How it works

|

A bucket elevator feeds materials into a rotating cylinder, where hot air from a blast furnace dries the materials

|

|

What it’s used for

|

Drying fertilizers, animal manure, and other materials

|

|

Benefits

|

Low noise, high efficiency, low energy consumption, and easy to operate

|

|

Features

|

Includes a rotary body, lifting plate, driving device, supporting device, and sealing ring

|

|

Other uses

|

Can be used in the bio-mass pellet industry, feed pellet industry, building materials drying, and more

|